| Light yellow powdery substance | |

| Name, symbol, number | Sulfur/Sulfur (S), 16 |

| Atomic mass (molar mass) | [32.059; 32.076]a. e.m. (g/mol) |

| Electronic configuration | [Ne] 3s2 3p4 |

| Atomic radius | 127 pm |

| Covalent radius | 102 pm |

| Ion radius | 30 (+6e) 184 (−2e) pm |

| Electronegativity | 2.58 (Pauling scale) |

| Electrode potential | 0 |

| Oxidation states | +6, +4, +2, +1, 0, −1, −2 |

| Ionization energy (first electron) | 999.0 (10.35) kJ/mol (eV) |

| Density (at normal conditions) | 2.070 g/cm³ |

| Melting temperature | 386 K (112.85 °C) |

| Boiling temperature | 717.824 K (444.67 °C) |

| Ud. heat of fusion | 1.23 kJ/mol |

| Ud. heat of vaporization | 10.5 kJ/mol |

| Molar heat capacity | 22.61 J/(K mol) |

| Molar volume | 15.5 cm³/mol |

| Lattice structure | orthorhombic |

| Lattice parameters | a = 10.437, b = 12.845, c = 24.369 Å |

| Thermal conductivity | (300 K) 0.27 W/(m K) |

| CAS number | 7704-34-9 |

| GOST | GOST 127.1-93 GOST 127.4-93 GOST 127.5-93 GOST R 56249-2014 |

STRUCTURE

Crystal structure and two systems of sulfur

Native sulfur is usually represented by a-sulfur, which crystallizes in the rhombic system, rhombic-bipyramidal type of symmetry. Crystalline sulfur has two modifications; one of them, orthorhombic, is obtained from a solution of sulfur in carbon disulfide (CS2) by evaporating the solvent at room temperature. In this case, diamond-shaped translucent crystals of light yellow color are formed, easily soluble in CS2. This modification is stable up to 96°C; at higher temperatures the monoclinic form is stable. With the natural cooling of molten sulfur in cylindrical crucibles, large crystals of the orthorhombic modification with a distorted shape (octahedra with corners or faces partially “cut off”) grow. This material is called lump sulfur in industry. The monoclinic modification of sulfur is long transparent dark yellow needle-shaped crystals, also soluble in CS2. When monoclinic sulfur is cooled below 96° C, a more stable yellow orthorhombic sulfur is formed.

Sulfur price

According to the latest news, the need for sulfur is actively growing. The cost of a Russian product is 130 dollars. For the Canadian version – $145. But in the Middle East, prices increased to $8, resulting in a cost of $149.

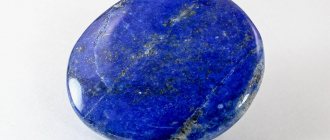

The photo shows a large specimen of the mineral sulfur

In pharmacies you can find ground sulfur powder at a price of 10 to 30 rubles. In addition, it is possible to buy it in bulk. Some organizations offer to purchase granular technical gas sulfur .

PROPERTIES

Native sulfur

Native sulfur is yellow in color, in the presence of impurities it is yellow-brown, orange, brown to black; contains inclusions of bitumen, carbonates, sulfates, and clay. Crystals of pure sulfur are transparent or translucent, solid masses are translucent at the edges. The shine is resinous to greasy. Hardness 1-2, no cleavage, conchoidal fracture. Density 2.05 -2.08 g/cm3, brittle. Easily soluble in Canada balsam, turpentine and kerosene. Insoluble in HCl and H2SO4. HNO3 and aqua regia oxidize sulfur, turning it into H2SO4. Sulfur differs significantly from oxygen in its ability to form stable chains and cycles of atoms. The most stable are the crown-shaped cyclic S8 molecules, which form orthorhombic and monoclinic sulfur. This is crystalline sulfur - a brittle yellow substance. In addition, molecules with closed (S4, S6) chains and open chains are possible. This composition has plastic sulfur, a brown substance, which is obtained by sharp cooling of molten sulfur (plastic sulfur becomes brittle after a few hours, acquires a yellow color and gradually turns into rhombic). The formula for sulfur is most often written simply S, since, although it has a molecular structure, it is a mixture of simple substances with different molecules. The melting of sulfur is accompanied by a noticeable increase in volume (approximately 15%). Molten sulfur is a yellow, easily mobile liquid, which above 160 °C turns into a very viscous dark brown mass. The sulfur melt acquires the highest viscosity at a temperature of 190 °C; a further increase in temperature is accompanied by a decrease in viscosity and above 300 °C the molten sulfur again becomes mobile. This is because when sulfur is heated, it gradually polymerizes, increasing the length of the chain as the temperature increases. When sulfur is heated above 190 °C, the polymer units begin to collapse. Sulfur can serve as the simplest example of an electret. When rubbed, sulfur acquires a strong negative charge.

Historical perspective

It is not clear when sulfur was discovered and its mining began. What is known is that ancient people knew about it long before our era. Early priests used it in their cult rituals and included it in fumigation mixtures. The mineral sulfur was considered a product produced by the gods, who mainly lived in the underworld.

You might be interested in:Phrasal verb give: meanings and exercises

For a long time, as evidenced by historical documents, it was used as a component of flammable mixtures that were used for military purposes. Homer also did not ignore the mineral sulfur. In one of his works, he described “vapors” that had a detrimental effect on humans when burned.

Historians suggest that sulfur was an element in the so-called “Greek fire”, which struck fear into enemies.

In the eighth century in China, it began to be used to prepare pyrotechnic mixtures, including flammable substances resembling gunpowder.

Channel PROGRAMMER'S DIARY

The life of a programmer and interesting reviews of everything. Subscribe so you don't miss new videos.

In the Middle Ages, it was one of the three main elements of alchemists. They actively used the mineral native sulfur in their research. This often led to the fact that experiments with it were equated with witchcraft, and this in turn led to persecution by the Inquisition of ancient chemists and their followers. It was from those times, from the Middle Ages and the Renaissance, that the smell of burning sulfur and their gases began to be associated with the acts of evil spirits and devilish manifestations.

MORPHOLOGY

Native sulfur

Forms truncated-bipyramidal, less often bipyramidal, pinacoidal or thick-prismatic crystals, as well as dense cryptocrystalline, confluent, granular, and less often fine-fibrous aggregates. The main forms in crystals: dipyramids (111) and (113), prisms (011) and (101), pinacoid (001). Also intergrowths and druses of crystals, skeletal crystals, pseudostalactites, powdery and earthy masses, deposits and adhesives. Crystals are characterized by multiple parallel intergrowths.

General characteristics of elements of group 6 of the main subgroup

From O to Po (from top to bottom in the periodic table)

Increases

- atomic radius,

- metallic, basic, reducing properties,

Decreases

- electronegativity,

- ionization energy,

- electron affinity.

The electronic configurations of these elements are similar; they all contain 6 electrons in the ns2np4 outer layer:

O – 2s2 2p4;

S – 3s23p4;

Se – 4s2 4p4;

Te – 5s2 5p4;

Po – 6s2 6p4

Electronic structure of oxygen and sulfur

ORIGIN

Native sulfur

Sulfur is formed during volcanic eruptions, during the weathering of sulfides, during the decomposition of gypsum-bearing sedimentary strata, and also in connection with the activity of bacteria. The main types of native sulfur deposits are volcanogenic and exogenous (chemogenic-sedimentary). Exogenous deposits predominate; they are associated with gypsum anhydrites, which, under the influence of hydrocarbon and hydrogen sulfide emissions, are reduced and replaced by sulfur-calcite ores. All major deposits have such infiltration-metasomatic genesis. Native sulfur is often formed (except in large accumulations) as a result of the oxidation of H2S. The geochemical processes of its formation are significantly activated by microorganisms (sulfate-reducing and thionic bacteria). Associated minerals are calcite, aragonite, gypsum, anhydrite, celestine, and sometimes bitumen. Among the volcanogenic deposits of native sulfur, the main ones are hydrothermal-metasomatic (for example, in Japan), formed by sulfur-bearing quartzites and opalites, and volcanogenic-sedimentary sulfur-bearing silts of crater lakes. It is also formed during fumarole activity. Formed under the conditions of the earth's surface, native sulfur is still not very stable and, gradually oxidizing, gives rise to sulfates, ch. like plaster. Used in the production of sulfuric acid (about 50% of the extracted amount). In 1890, Hermann Frasch proposed smelting sulfur underground and extracting it to the surface through wells, and currently sulfur deposits are developed mainly by smelting native sulfur from underground layers directly at its location. Sulfur is also found in large quantities in natural gas (in the form of hydrogen sulfide and sulfur dioxide); during gas production, it is deposited on the walls of pipes, rendering them inoperable, so it is recovered from the gas as quickly as possible after production.

Receipt

In ancient times and in the Middle Ages, sulfur was mined by digging a large clay pot into the ground, on which another was placed, with a hole in the bottom. The latter was filled with rock containing sulfur and then heated. The sulfur melted and flowed into the lower pot.

Currently, sulfur is obtained mainly by smelting native sulfur directly in places where it occurs underground. Sulfur ores are mined in different ways, depending on the conditions of occurrence. Sulfur deposits are almost always accompanied by accumulations of poisonous gases - sulfur compounds. In addition, we must not forget about the possibility of its spontaneous combustion.

When mining ore in an open pit, excavators remove layers of rock under which the ore lies. The ore layer is crushed by explosions, after which the ore blocks are sent to a sulfur smelter, where sulfur is extracted from the concentrate.

In 1890, Hermann Frasch proposed melting sulfur underground and pumping it to the surface through oil wells. The relatively low (113 °C) melting point of sulfur confirmed the reality of Frasch’s idea. In 1890, tests began that led to success.

There are several known methods for obtaining sulfur from sulfur ores: steam-water, filtration, thermal, centrifugal and extraction.

Granulated sulfur

Sulfur is also contained in large quantities in natural gas in a gaseous state (in the form of hydrogen sulfide, sulfur dioxide). During mining, it is deposited on the walls of pipes and equipment, rendering them inoperable. Therefore, it is recovered from the gas as quickly as possible after production. The resulting chemically pure fine sulfur is an ideal raw material for the chemical and rubber industries.

Sulfur is obtained from natural sulfur dioxide using the Claus method. For this purpose, so-called sulfur pits are used, where sulfur is degassed, resulting in modified sulfur - a product widely used in the production of asphalt. Sulfur production plants typically include non-degassed sulfur pits, degassed sulfur pits, degassed sulfur storage pits, as well as liquid sulfur loading and lump sulfur storage. The walls of the pit are usually made of brick, the bottom is filled with concrete, and the pit is covered with an aluminum roof on top. Since sulfur is a very aggressive environment, the pits periodically have to be completely reconstructed.

The largest deposit of native sulfur of volcanic origin is located on the island of Iturup with reserves of category A+B+C1 - 4227 thousand tons and category C2 - 895 thousand tons, which is enough to build an enterprise with a capacity of 200 thousand tons of granulated sulfur per year.

Sulfur warehouse near the chemical workshop of MMSC (1960s)

Manufacturers

From 1939 to 1986, the largest sulfur producer in the USSR was the Mednogorsk Copper and Sulfur Combine (MMSC): in the mid-1950s it produced up to 250-280 thousand tons per year, which accounted for 80% of the sulfur produced in the country.

...In the morning we were at the copper sulfur plant. About 80 percent of the sulfur produced in our country is mined at this enterprise.

— Until 1950, the country had to import a lot of sulfur from abroad. Now there is no need to import sulfur, said plant director Alexander Adolfovich Burba. “But the plant continues to expand. We began to build a sulfuric acid production workshop.

A bright yellow mass of sulfur hung from a high overpass like a frozen stream. What we see in small quantities in glass jars in laboratories lay here in the factory yard in huge lumps.”

- A. Sofronov. In the Orenburg steppes (Ogonyok magazine, 1956)

At the beginning of the 21st century, the main producers of sulfur in Russia are the enterprises of OJSC Gazprom: LLC Gazprom Dobycha Astrakhan and LLC Gazprom Dobycha Orenburg, which receive it as a by-product during gas purification.

Product forms

The industry has realized the production of sulfur in various commercial forms.

The choice of one form or another is determined by the customer’s requirements. Lump sulfur

Until the early 1970s, it was the main type of sulfur produced by industry in the USSR. Its production is technologically simple and is carried out by supplying liquid sulfur through a heated pipeline to a warehouse where sulfur blocks are poured. Frozen blocks 1-3 meters high are destroyed into smaller pieces and transported to the customer. The method, however, has disadvantages: low quality of sulfur, losses due to dust and crumbs during loosening and loading, and complexity of automation.

Liquid sulfur

stored in heated tanks and transported in tanks. Transporting liquid sulfur is more profitable than melting it on site. The advantages of obtaining liquid sulfur are the absence of losses and high purity. Disadvantages - danger of fire, expenses for heating tanks.

Molded sulfur

There are scaly and lamellar. Flake sulfur began to be produced at refineries in the 1950s. To obtain it, a rotating drum is used; inside it is cooled with water, and outside, sulfur crystallizes in the form of flakes 0.5-0.7 mm thick. In the early 1980s, lamellar sulfur began to be produced instead of flake sulfur. Molten sulfur is supplied to the moving belt, which cools as the belt moves. At the exit, a frozen sheet of sulfur is formed, which is broken to form plates. Today this technology is considered obsolete, although about 40% of Canadian sulfur is exported in this form due to the large capital investments in plants for its production.

Granulated sulfur

obtained by various methods.

- Water granulation (pelletizing) was developed in 1964 by the English. The process is based on the rapid cooling of sulfur droplets falling into water. The first introduction of the technology was the Salpel process in 1965. The largest plant was later built in Saudi Arabia in 1986. On it, each of the three installations can produce up to 3,500 tons of granulated sulfur per day. The disadvantage of the technology is the limited quality of sulfur granules, which have an irregular shape and increased fragility.

- Fluidized bed granulation was developed by the French. Drops of liquid sulfur flow upward. They are cooled with water and air and moistened with liquid sulfur, which hardens into a thin layer on the resulting granules. The final granule size is 4-7 mm. More progressive is the “Prokor” process, which is widely implemented in Canada. It uses drum granulators. However, this process is very difficult to manage.

- Air tower granulation was developed and introduced in Finland in 1962. The molten sulfur is dispersed using compressed air at the top of the granulation tower. The drops fall and harden as they fall onto the conveyor belt.

Ground sulfur

is a product of grinding lump sulfur. The degree of grinding may vary. It is carried out first in a crusher, then in a mill. In this way it is possible to obtain very highly dispersed sulfur with a particle size of less than 2 microns. Granulation of powdered sulfur is carried out in presses. It is necessary to use binding additives, which include bitumen, stearic acid, fatty acids in the form of an aqueous emulsion with triethanolamine, and others.

Colloidal sulfur

is a type of ground sulfur with a particle size of less than 20 microns. It is used in agriculture for pest control and in medicine as an anti-inflammatory and disinfectant. Colloidal sulfur is obtained in various ways.

- The method of production by grinding is widespread because it does not place high demands on raw materials. One of the leaders in this technology is.

- The method of producing sulfur from molten sulfur or its vapor was introduced in the USA in 1925. The technology involves mixing with bentonite, the resulting mixture forms stable suspensions with water. However, the sulfur content in the solution is low (no more than 25%).

- Extraction methods of production are based on the dissolution of sulfur in organic solvents and the further evaporation of the latter. However, they are not widely used.

High purity sulfur

obtained using chemical, distillation and crystallization methods. It is used in electronic equipment, in the manufacture of optical instruments, phosphors, in the production of pharmaceuticals and cosmetics - lotions, ointments, and products against skin diseases.

APPLICATION

Sulfur is part of the match head

Approximately half of the sulfur produced is used in the production of sulfuric acid. Sulfur is used for vulcanization of rubber, as a fungicide in agriculture and as colloidal sulfur - a medicinal product. Also, sulfur in sulfur bitumen compositions is used to produce sulfur asphalt, and as a substitute for Portland cement to produce sulfur concrete. Sulfur is used for the production of pyrotechnic compositions, was previously used in the production of gunpowder, and is used for the production of matches.

Sulfur (eng. Sulfur) - S

| Molecular weight | 32.06 g/mol |

| origin of name | Latin sulfur (derived from the Hellenized spelling of the etymological sulpur) presumably goes back to the Indo-European root *swelp - “to burn” |

| IMA status | valid, first described before 1959 (before IMA) |

Biological role

Sulfur is one of the biogenic elements. Sulfur is part of some amino acids (cysteine, methionine), vitamins (biotin, thiamine), and enzymes. Sulfur is involved in the formation of protein tertiary structure (formation of disulfide bridges). Sulfur is also involved in bacterial photosynthesis (sulfur is part of bacteriochlorophyll, and hydrogen sulfide is a source of hydrogen). Redox reactions of sulfur are a source of energy in chemosynthesis.

A person contains approximately 2 g of sulfur per 1 kg of body weight.

Biological action

Pure sulfur is not poisonous, but volatile sulfur-containing compounds are poisonous (sulfur dioxide, sulfuric anhydride, hydrogen sulfide, etc.).

Sulfur soap

PHYSICAL PROPERTIES

| Mineral color | yellow, sulfur yellow, brownish or greenish yellow, orange, white |

| Stroke color | colorless |

| Transparency | transparent, translucent |

| Shine | tarry, greasy |

| Cleavage | imperfect on {001}, {110} and {111} |

| Hardness (Mohs scale) | 1.5 — 2.5 |

| Kink | uneven, conchoidal |

| Strength | very fragile |

| Separateness | separate by {111} |

| Density (measured) | 2.07 g/cm3 |

| Radioactivity (GRapi) | 0 |